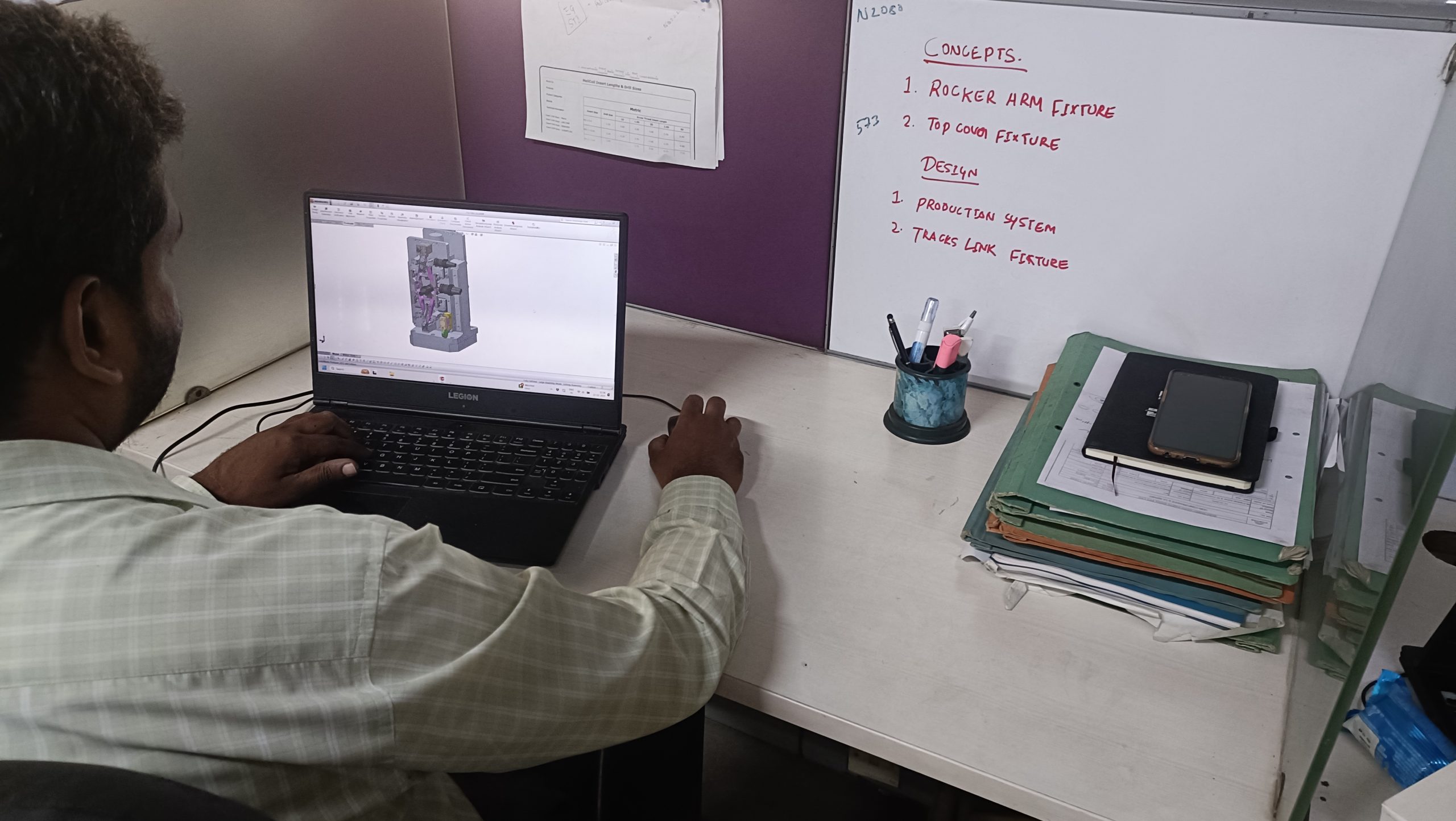

Design

We have experienced design engineers with hands on experience in designing a variety of fixtures as per customer requirement. Our design team is proficient in designing fixtures for HMCs, VMCs – flat fixtures and rotary fixtures and also fixtures for 5 axis machines. Clamping method used is hydraulic/pneumatic/manual as per customer requirement. Our design team utilizes 3D modelling for designing.

Quality

We have a dedicated facility for checking the quality of each and every part used in the assembly. Using digital height master and other QC instruments, our team ensures that the parts are as per spec.

Assembly and Testing

We have a full-fledged assembly and testing facility inhouse. Component clamping trials are done on all fixtures before dispatch to ensure proper clamping and also to ensure that the position of the component is not disturbed and the component does not deform due to clamping.

Machining

We have VMCs which we utilize to manufacture critical fixture parts and also to provide part manufacturing service to our clients in the automotive and defense sector. 3 of our 4 VMCs have 4th axis indexers which enhance the capability of the machine and allows us to machine intricate parts with optimal cycle times and precision

VMC Programming

Our programming department utilizes the latest programming software to program VMCs to carry out machining. Cutting parameters are selected according to the material and cutting operation. Tool paths are optimized to achieve minimal possible cycle time while ensuring required precision on the part.

Component Washing

After components are machined, they are washed in ultrasonic washing machine and dried with compressed air. This ensures that the components are lubricant free.

Final Inspection

All components machined inhouse are 100% inspected before delivery. Using gauges, our Final inspection team ensures that all the components are as per drawing.